INNOVATION AND TRADITION IN THE PRODUCTION OF ABRASIVE WHEELS SINCE 1968

Leader in the supply of abrasive solutions for a wide range of applications.

ABRASIVES

The abrasive is the primary component that gives the wheel the ability to perform precise machining.

Each individual grain of abrasive precisely removes tiny fragments of the material being worked.

The main abrasives used in the production processes of our wheels include:

ABRASIVES

CORUNDUM

A chemical product obtained by melting pure alumina minerals in an electric furnace, classified according to the content of aluminum oxide (Al2O3) and the additives present. Main types include:

ABRASIVES

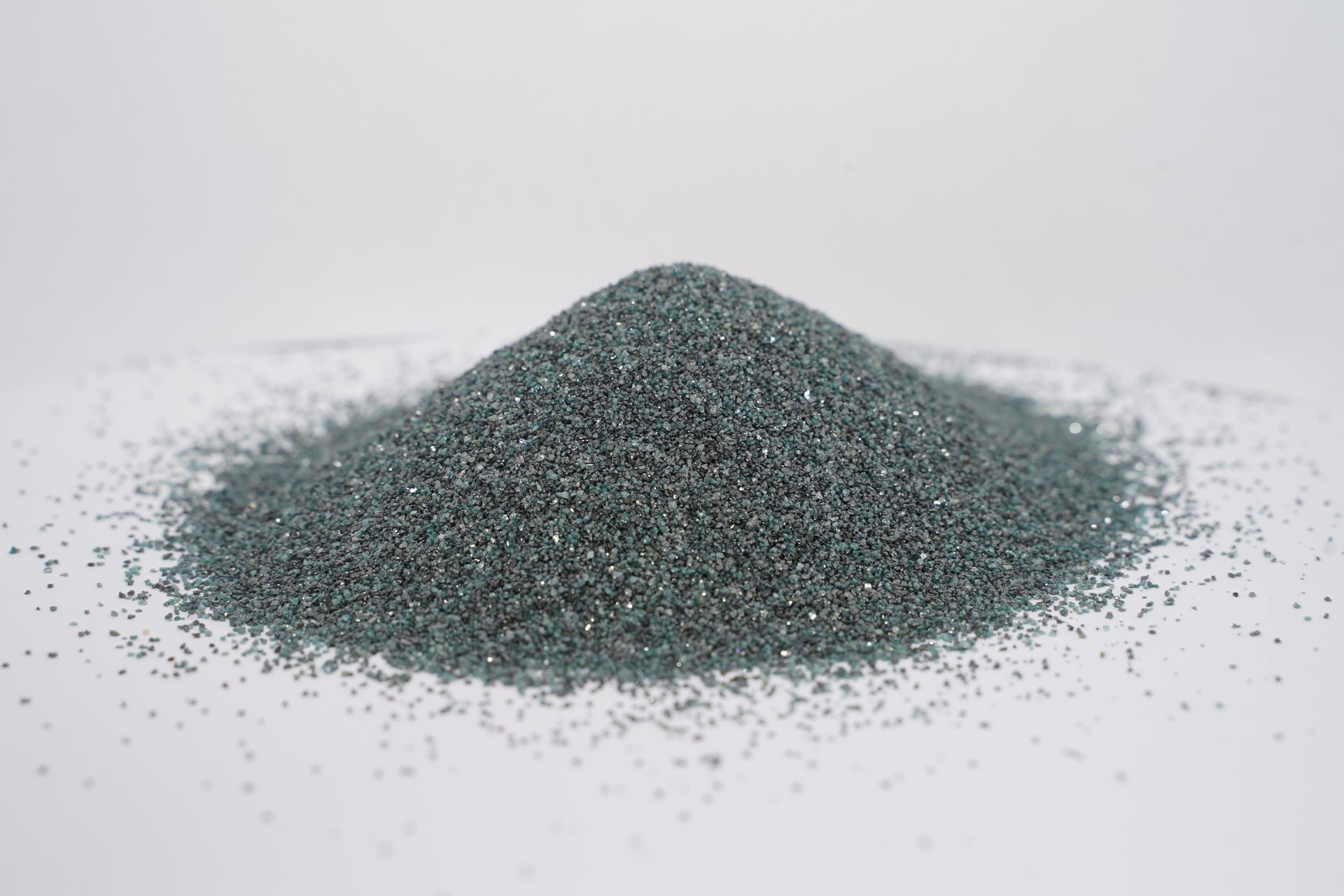

SILICON CARBIDE

Obtained from the chemical combination of pure carbon and silicon during a high-temperature process in an electric furnace, corundums occur in crystals of varying colors, which can be shiny black, gray, or light green. Despite their high hardness, they are also brittle and are mainly used in the processing of materials less resistant to tension, such as cast iron, aluminum, copper, and brass, but also in extremely hard materials such as carbide, glass, and ceramics. The main types of corundums include:

Send a message

Questions? We are here to help you. Send us a message to be contacted.